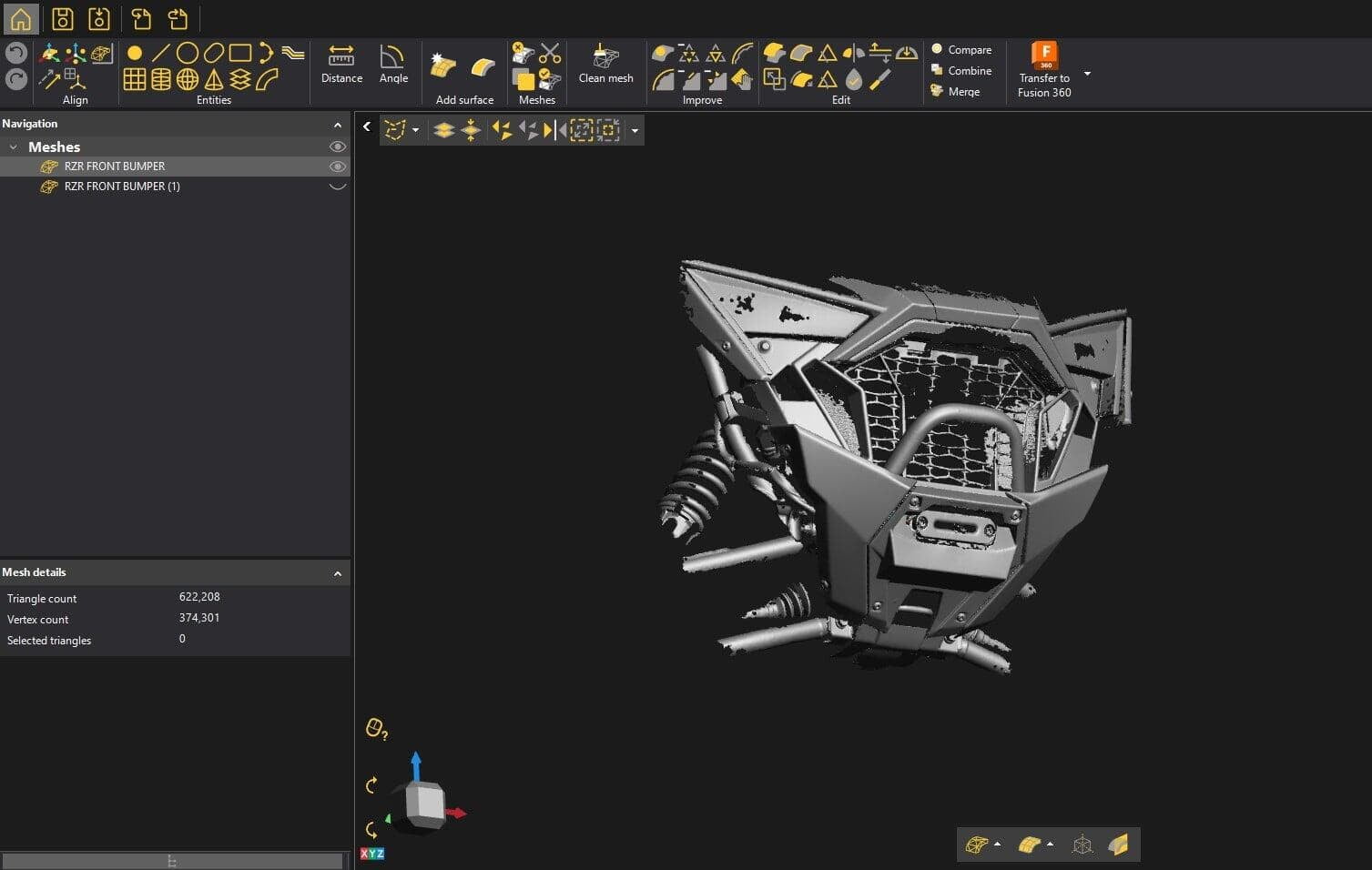

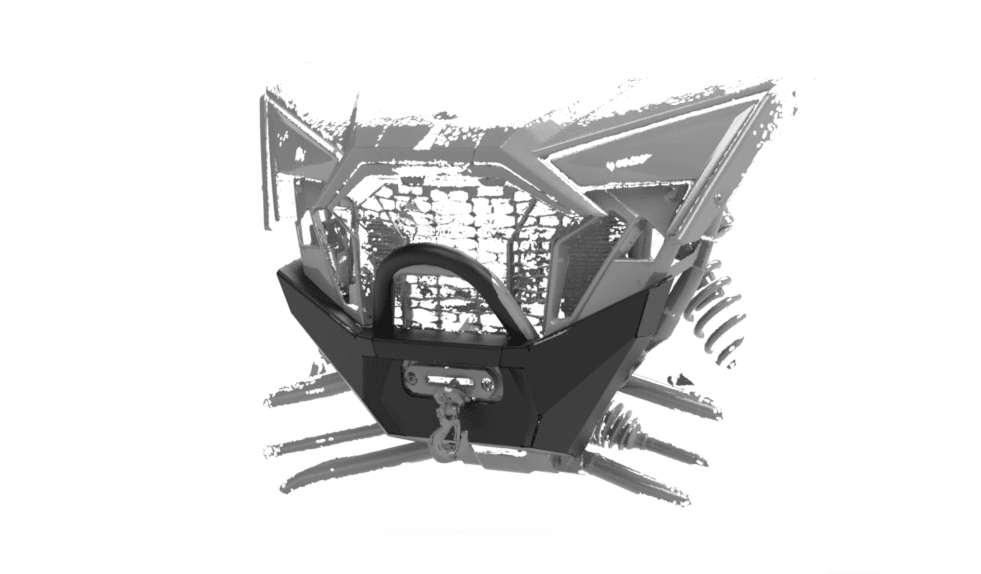

3D Scanning & Reverse Engineering for Product Design

Designing parts around existing 3D geometry, simple or complex, can be both time consuming and expensive. Save that time and effort and work with EMTECH to capture the geometry with a 3D scan and reverse engineering CAD model so that your product can be designed accurately the first time, plus the resulting 3D CAD will be available for any future designs needs as well.